SABIC, BASF and Linde officials at the inauguration

SABIC, BASF and Linde officials at the inauguration

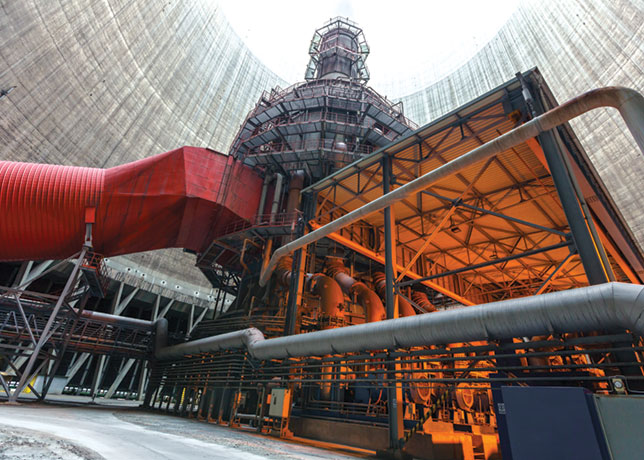

BASF, SABIC, and Linde have inaugurated the world’s first demonstration plant for large-scale electrically heated steam cracking furnaces.

Following three years of development, engineering, and construction work, the regular operation of the demonstration plant is now ready to start at BASF’s Verbund site in Ludwigshafen, Germany.

In March 2021 the three companies signed a joint agreement to develop and demonstrate solutions for electrically heated steam cracking furnaces.

Steam crackers play a central role in the production of basic chemicals and require a significant amount of energy to break down hydrocarbons into olefins and aromatics.

Typically, the reaction is conducted in furnaces at temperatures of about 850 deg C. Up to now, these temperatures have been reached by using conventional fuels.

The demonstration plant aims to show that continuous olefin production is possible using electricity as a heat source.

By using electricity from renewable sources, the new technology has the potential to reduce CO2 emissions of one of the most energy-intensive production processes in the chemical industry by, at least, 90 per cent compared to technologies commonly used today.

The demonstration plant, which produces olefins, such as ethylene, propylene, and possibly also higher olefins from saturated hydrocarbon feedstock, is fully integrated into the existing steam crackers in Ludwigshafen.

The upcoming operation serves the goal of gathering data and experiences about material behavior and processes under commercial operating conditions for the final development of this innovative technology to industrial market maturity.

In two separate demonstration furnaces, two different heating concepts will be tested.

While in one furnace, direct heating applies an electric current directly to the cracking coils, in the second furnace, indirect heating uses radiative heat of heating elements placed around the coils.

The two electrically heated furnaces together process around 4 tons of hydrocarbon feedstock per hour and consume 6 megawatts of renewable energy.

To support the development of the novel furnace technology, the project was granted €14.8 million ($15.8 million) by the German Federal Ministry for Economic Affairs and Climate Action under its 'Decarbonisation in Industry' funding programme.

The programme is supporting energy-intensive industries in Germany in their efforts to achieve carbon neutrality.

Abdulrahman Al-Fageeh, CEO of SABIC stated; "The e-furnace’s technology holds huge potential for the sustainability of the global petrochemical industry."