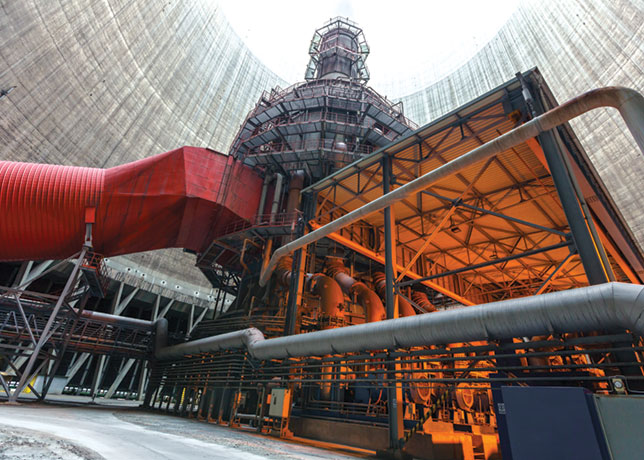

Souring spare parts for petrochemical plants and refineries is a challenge

Souring spare parts for petrochemical plants and refineries is a challenge

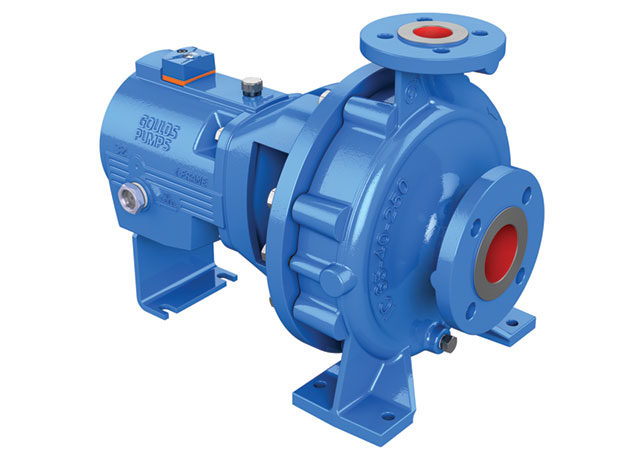

The majority of petrochemical process engineers have reported issues sourcing spare parts for temperature control equipment at petrochemical plants and refineries, potentially disrupting operations subject to seasonal demand.

According to a survey by Aggreko of over 600 engineers from the UK, Germany, France, Belgium, the Netherlands and Luxembourg, an average of 52 per cent of respondents cited issues sourcing spare parts for cooling, heating, steam and compressed air equipment.

These findings, gathered by independent research partner Censuswide to inform Aggreko’s new whitepapers, titled ‘Process Matters’, identify multiple operational challenges in the sector.

This includes ageing existing process and temperature control equipment in all markets questioned, with solutions being five years old on average and many being even older.

According to Jordi Camanyes, Petrochemical and Refining Sector Leader – Europe for Aggreko, these findings, combined with other market pressures, could pose challenges for the sector.

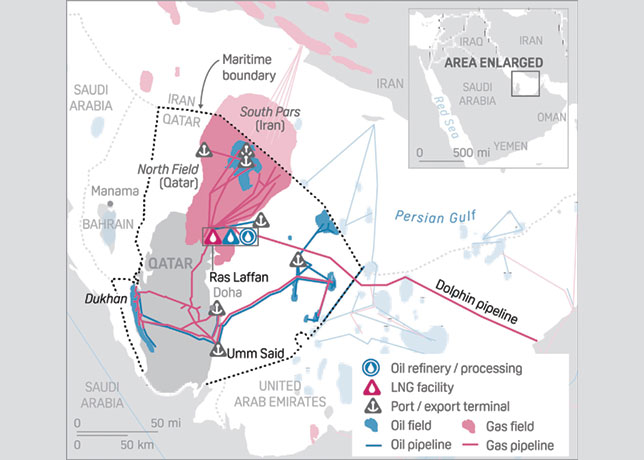

"The European petrochemical sector continues to be affected by multiple fluctuating factors, including rising feedstock costs and volatile oil and gas pricing," he explains.

Yet certain constants remain, including that it will get colder in the winter. Petrochemical plants should, therefore, adapt their temperature control arrangements accordingly.

"However, as our most recent reports clearly identify, the heating and cooling equipment currently used in refineries are of advanced age, with all the wear-and-tear and potential downtime that entails. Yet though problems sourcing spare parts may create a more challenging situation, there are also clear opportunities for improvement," says Camanyes.

Stakeholders looking to upgrade existing equipment also need to consider sustainability-minded legislation such as the EU’s transition pathway for petrochemicals, and the bloc’s new Energy Efficiency Directives for industry.

With legislation and greener energy solution technologies continuing to advance rapidly, Jordi is advocating adjusting equipment procurement strategies to include short-term bridging solutions, especially given enthusiasm from the report’s respondents for sustainable solutions.

"The reason for our new Process Matters reports and the research behind them was to explore ways to improve process performance and competitiveness at European petrochemical plants. To that end, the insights we have uncovered from surveying such a broad cross-section of sector engineers has been invaluable," says Camanyes.

For instance, despite current industry challenges, 95 per cent of respondents said they were willing to pay 25-50 per cent extra for greener utility solutions, and 94 per cent expected their suppliers to have a robust environmental and social responsibility strategy.

Camanyes says this will clearly have huge ramifications on how process and temperature control equipment is procured in the future.

"Suppliers must, therefore, ensure they can not only provide solutions on a dynamic, modular hire basis that suits the fast-moving petrochemical sector, but also that these technologies are efficient and sustainable."