MH Hydraulics FZC, a leading hydraulic solutions provider in the Middle East, highlights oil contamination in this edition of TechTalk, while explaining the best methods to prevent oil contamination with the help of DES-CASE RMF Systems, a market leader and manufacturer in filtration products, and desiccant breathers from the USA and the Netherlands.

In the previous TechTalk, published in September 2020, it discussed the importance of oil cleanliness for equipment.

How does oil contamination occur?

The most common channels of contamination ingress are:

• New oil;

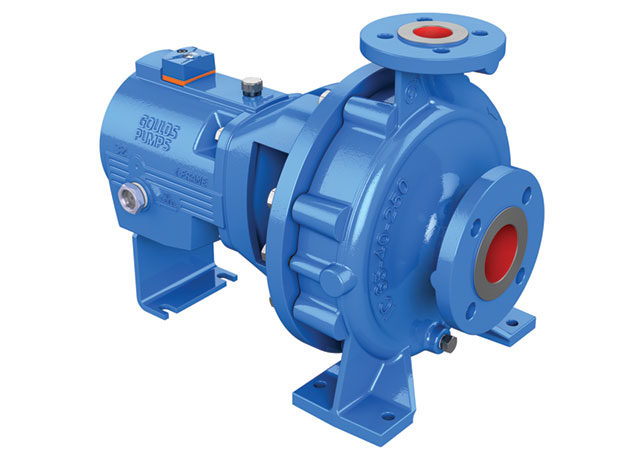

• Inlet and outlet vents, filling ports, breathers of hydraulic systems, gearboxes, pumps, etc.; and

• Hose replacements.

New oil is, in almost all cases, not fully clean. The inlet and outlet vents for the equipment makes it possible for particles and water contaminants present in the air to get into the system which will then lead to oil contamination. Negative consequences are coupled with oil contamination issues, such as decline in equipment performance, productivity, efficiency, and most importantly unscheduled costly component breakdown.

Equipment breathes when:

• The oil level fluctuates in the tank, mostly in hydraulic and lubrication circulation systems.

• There are temperature fluctuations; when the temperature in the headspace drops (usually at night), air will be sucked in.

Thus, when air flows into the asset, and this air is contaminated with small particles and moisture/humidity, the hydraulic oil/lubricant will get contaminated. Humidity will turn into condensation, which will cause surface corrosion in the headspace and water droplets will fall into the hydraulic oil/lubricant. Therefore “headspace management” is very important to keep the oil healthy.

DES-CASE breathers work both ways, when inhaling and exhaling. They absorb the moisture in the air, thus minimising condensation in the head space.

Common OEM breathers usually protect from larger debris falling into the reservoir; they don’t prevent moisture from getting in. Most OEM breathers need to be upgraded to include both particle removing and desiccating media to help prevent both solid contaminants and moisture from entering the machine. For this reason, we recommend desiccant breathers for the equipment.

Desiccant breathers not only prevent moisture from getting in, but they actively dehydrate the headspace as well, resulting in dryer oil. Desiccant breathers prevent small particles (3 micron and above) getting into the oil while OEM breathers typically filter 25 to 40 microns. Studies show it costs 10 times less to exclude contamination than to remove it. Desiccant breathers can extend machine component life by 3-8 times.

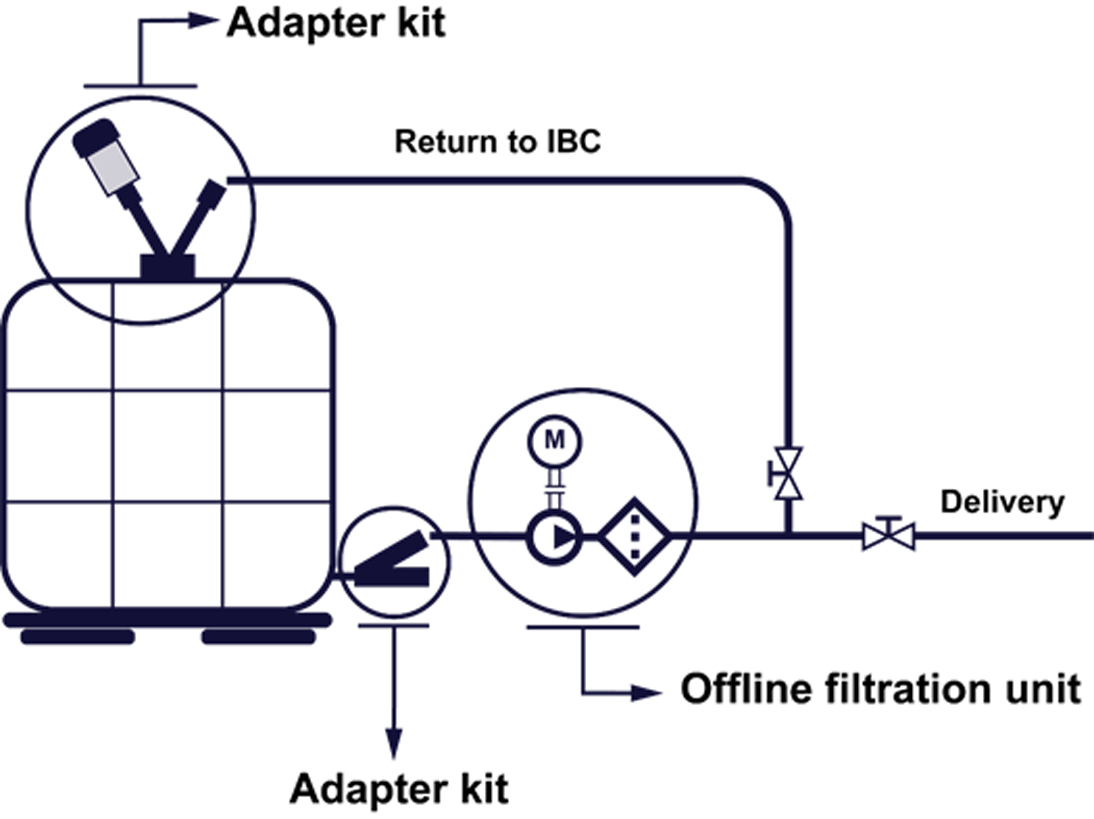

In addition, to fully minimise the possibility of air contaminants from entering the system, filling ports should be modified to allow oil to be added without exposing the machine to the ambient environment. The easiest way to achieve this is by using quick-connects and custom adapters that replace conventional fill ports.

Installing adaptor kit allows:

• Easy equipment adaptation and quick connection to a filtration system;

• Enables the possibility to extract, transfer, fill, and filter the oil;

• Sample tube for taking sample at right location are possible with adaptor kits;

• Oil level indication, vent tube connection;

• And other features to prevent oil contamination.

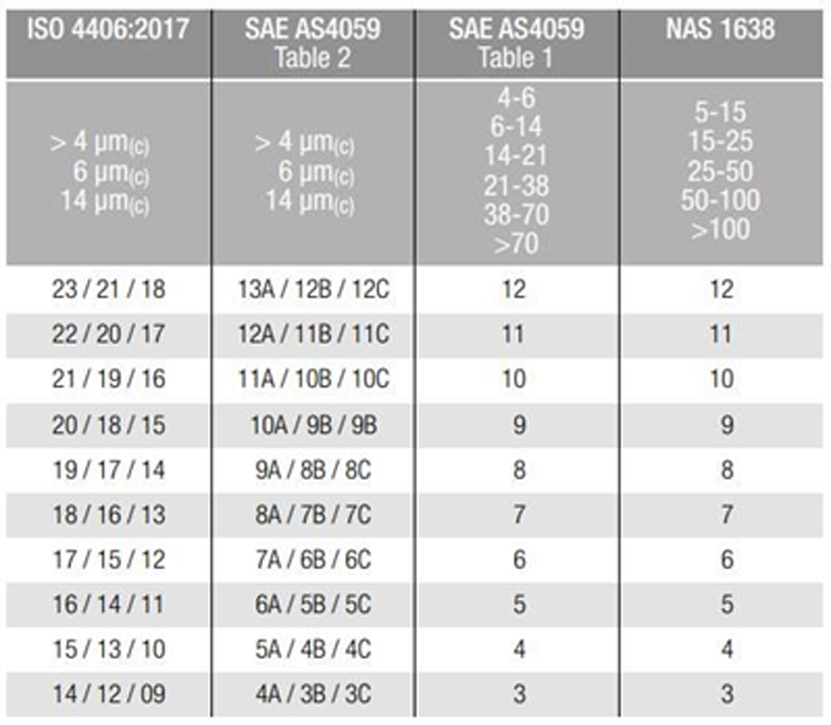

To ensure oil cleanliness, periodic monitoring of oil quality is required. ISO 4406:2017 standard is popularly used in the hydraulics industry for indictating oil cleanliness. This table shows a comparison of different standards used worldwide:

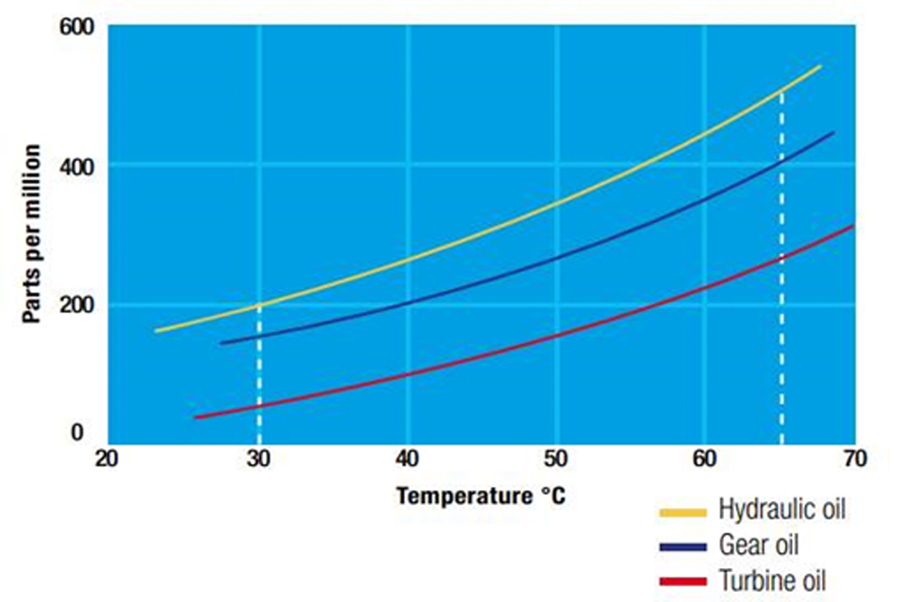

Water is an undesirable element in mineral oil and and non-aqueous resistant fluids. The water content of mineral oil is usually 50-300 ppm (at 40 deg C) which it can support without adverse consequences.

Oil starts to appear hazy once the water content goes above 300 ppm. At this stage, there is a danger of free water accumulating in the system in areas of low flow and it can lead to corrosion and accelerated wear.

To sum it up, it is highly recommended to upgrade the hydraulic/lubrication system with a suitable desiccant breather and make use of adapter kits to avoid contamination during filling, transfer, inspection, etc.

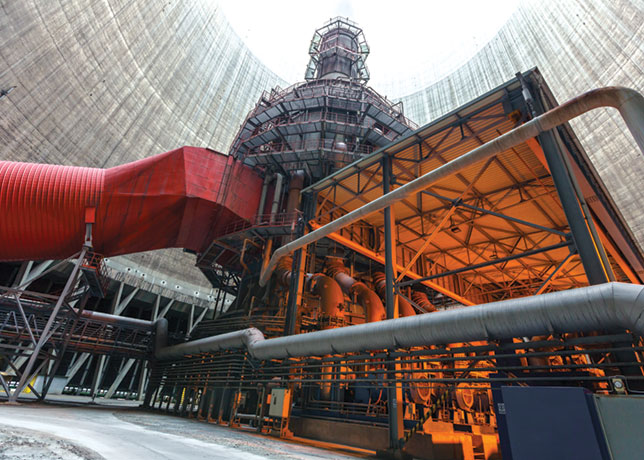

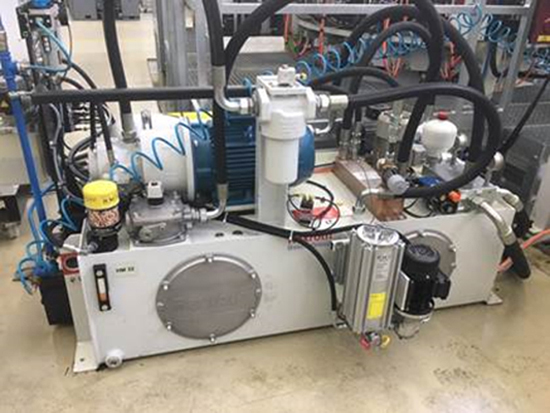

Example of a Hydraulic System equipped with RMF Desiccant Breather

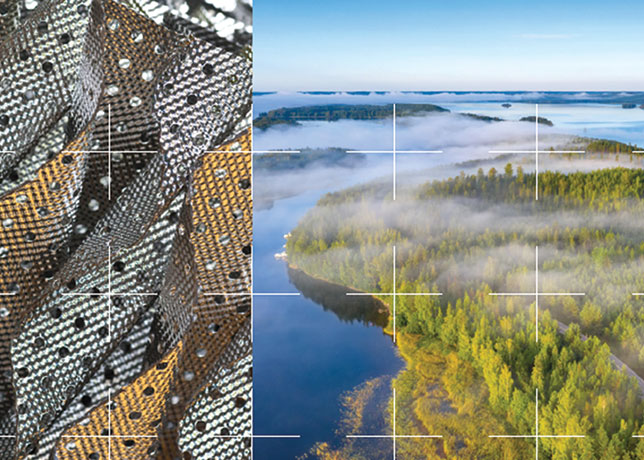

Examples of Hydraulic Systems modified with Des-Case Adapter Kits, to enable oil top-ups, level indication, taking oil samples, and drain oil.

* This article is supplied by MH Hydraulics